About Us

Ningbo Precision Machinery is located in Ningbo City, an important port city on the southeast coast. The company specializes in laser cutting, sheet metal bending, welding, painting, integrated processing of electronic control box assembly, cutting and processing of auto parts, hardware tool processing and other Sheet metal processing of various environmental protection equipment. Founded in 2012, it specializes in hardware processing, manufacturing and sales of various precision tooling fixtures and mechanical spare parts. With the concept of high quality, high efficiency and harmony, we have been committed to providing precision machine parts for domestic and foreign brand enterprises.After long-term cooperation with enterprises in various countries, it has reached international standards in terms of manpower, technology, products and management.

The company has 1 gantry CNC machining center, 14 CNC high-speed machining centers, 1 large-scale laser cutting machine, 8 CNC automatic lathes, 9 wire cutting machines, 24 milling machines, precision internal and external cylindrical grinders, large plane water mills, sandblasting machine, high frequency heat treatment, welding machine and other advanced equipment.The quality testing equipment includes high-precision projector, three-dimensional, two-dimensional, altimeter, hardness tester and other precision testing instruments. The company's business is not limited to industries, covering a wide range of industries, such as: mechanical and electrical engineering industry, automotive engineering industry, medical industry, mobile phone and other industries.

Products are mainly used in automated production equipment, automated testing equipment, automated packaging equipment, medical equipment and other equipment. we are China-Welding-Fabrication-Laser-Cutting-Bending-Stamping-Supplier-Factory-Manufacturer.

Our company has more than 6000 watts of Jinfangyuan bending machine, which can process large metal plates with a platform of 4000*2000, and meet your 25mm thick hot plate cutting. Equipped with a rotary processing platform, it can process and undertake all kinds of metal pipe cutting. We also It has a Fangyuan rotary bending machine, which can meet the bending of various types of plates with a length of 4,000. It provides precise sheet metal processing, structural welding, laser processing, blanking, chassis, electrical cabinets, environmental protection whitening, instrument detection shell processing and sheet metal processing. Metal processing factory / fixture customization / precision sheet metal processing factory / precision hardware parts processing / laser wire cutting processing / CNC parts processing / Shenzhen machining factory / precision fixture processing / CNC parts processing special material parts processing.We have professional practitioners who can customize all kinds of precision sheet metal products for you.

Scientific management and rigorous production enable our company to meet your high-quality and fast processing requirements! We wholeheartedly provide users with high-quality products and first-class services. Welcome friends to come to discuss cooperation!

WHY CHOOSE US?

NINGBO Precision is an industry leading, full-service machining and manufacturing service provider including a variety of welding and fabrication services for metal components. Bringing more than four decades of quality manufacturing processes to every project. We serves a wide range of customers in industries and applications such as agriculture, professional turf care, recreational marine, industrial equipment and components, precision metrology components, firearm components, oil & gas, petroleum, hydraulics and more.

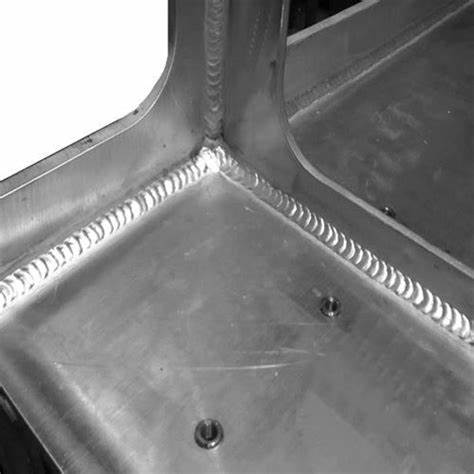

Metal Welding

Our welders provide a wide variety of Metal Welding processes to meet the needs and requirements of any steel or aluminum welding job, including contract jobs and production runs for small-to-medium-sized parts.

- FCA Welding: Otherwise known as Flux Core Arc Welding, similar to MIG welding, but uses a special steel electrode in place of the wire.

- MIG Welding: Also known as Gas Metal Arc Welding, forms an arc between a metal electrode and the work piece, melting the electrode to form a weld bead.

- TIG Welding: Also referred to as Gas Tungsten Arc Welding, is a cleaner method of welding for precision or where the job requires attractive aesthetics.

- Spot & Stud Welding: Commonly referred to as resistance welding, this method is widely used for joining sheets and components; and is performed using electrical current to heat metals and forge them together.

Fabrication

In addition to welding services, We also offers a range of fabrication services for metal fabrication designs.

Metal Fabrication

Metal manufacturing is the practice of designing and manufacturing high quality metal products according to specifications. We have trained metal fabricators can bend, shape and cut long lines of metal to make products such as Angle steels, casting substitutes, plates, panels, pipes and more.

Starting with raw materials such as sheet metal, bar, pipe or sheet metal, We can provide custom metal fabrication within the following parameters:

Material thickness must be between 0.03" and 3"

The length must be at least 1 inch and no more than 120 inches

Width must be at least ½ "and not more than 120"

Height must be at least ½ "and no higher than 36"

The weight should be between 0.5 pounds. Up to 2,000 pounds.

Our Metal Fabrication Services are carried out within 1/16 inch (+/-) tolerances.

In order to provide quality, efficient processes, all We services are backed by sustainable manufacturing practices such as six Sigma codes -- Black Belt, Lights Out/Unmanned Manufacturing, and Lean manufacturing. We are also ISO 9001:2015 certified.

Each job, large or small, is quoted individually, so whether your current project requires a prototype, a small run, or you are ready to scale up to full production, contact Us so we can start building your custom quote immediately.

Our Welding Highlights

1. General Capabilities

Contract or Custom

Production: Small & Medium Parts

2. Arc/Resistance Welding Process

FCAW (Flux Core Arc Welding)

This process uses similar equipment as GMAW but in place of standard solid wire uses wire consisting of a steel electrode surrounding a powder fill material.

GMAW (Gas Metal Arc Welding) :Also known as metal inert gas or MIG welding.

GTAW (Gas Tungsten Arc Welding) :Also known as Tungsten Inert Gas (TIG) welding. This process uses a non consumable tungsten electrode, an inert gas and a separate filler material. This process is sometimes mistakenly referred to as Heliarc welding.

MIG:Metal Inert Gas welding, also referred to as Gas Metal Arc Welding.

Spot :Spot welding is form of resistance welding used to join overlapping metal sheets. Two electrodes are used to clamp the sheets together and pass the current between them.

Stud Stud welding is a form of Spot welding where a bolt or weld nut is welded to another metal part. The bolts are often fed automatically into the welder.

TIG: Tungsten Inert Gas welding. Also referred to as Gas Tungsten Arc Welding.

Metal Fabrication Highlights we provide:

1. General Capabilities Small Components & Large Components.

2. Fabrication Method

Bending CNC Machining

Cut-Off, Cutting Die Cast, Drawn

Extrusion Laser Microfabricating

Laser Welding Machining

Sawing Screw Machining Welding

3. Material

Abrasion Resistant Plate

Alloy Aluminum

Brass Bronze Carbon Steel Copper

Heat Resistant Metals

Heat Resistant Steels

Iron Lead Light Metal

Perforated Metal

Sheet Metal Stainless Steel Steel

Steel Plate Structural Steel

Material Thickness

Min: .03 in

Max: 3 in

Length

Min: 1 in

Max: 120 in

Width

Min: .5 in

Max: 120 in

Height

Min: .5 in

Max: 60 in

Weight

Min: .5lb

Max: 2,000lb

Tolerance (+/-)

.03 in

4. Fabricated Products

Angles, Castings, Heavy Plate, Panels, Plates, Debar, Tooling, Tubes, Tubing.

MIG and TIG Welding Differences

5. Industry Focus we provide.

Advertising

Agricultural & Farming

Alternative Energy (see Power Generation)

Automation

Building & Construction

Commercial

Construction

Dairy

Defense Industry

Department of Energy (DOE)

Department of Defense (DOD)

Electrical

Energy (See Power Generation)

Food Production

Food Processing

Food & Beverage

Fracking

Government

Heavy Equipment

Hydraulics

Ice Making

Industrial

Injection Molding

Laboratory

Laundry

Natural Gas

Machine Tools

Machinery

Manufacturing

Marine

Material Handling & Processing

Medical Devices

Military

Mining

Nuclear (see Power Generation)

Oil Field

Oil, Gas, Petroleum Parts & Components

Packaging

Packaging & Converting

Paper & Pulp

Paper Mill

Petrochemical

Plumbing

Pneumatics

Power Generation

Power Generation Nuclear

Power Generation Alternative

Power Generation Solar

Power Generation Wind

Power Generation Coal

Power Generation NG

Printing

Printing & Publishing

Pulp & Paper

Pulp Manufacturing

Pumps

Railroad

Recreational

Research

Restaurant

Robotics

Specialty Machinery

Tool & Die

Transportation

Turf & Garden

Universities & Learning Institutions

Waste Management

Wastewater

Water & Wastewater Treatment

All Types of Metal Fabrication Services we can do for you:

We are professional steel Metal Fabrication Services and metal precision Processing factory, with low costs and fast delivery promise, we can maximum to gain benefit for our customers.

1. Metal Fabrication Services Materials

We are Metal Fabrication Services Company. We can provide below details:

· Ferrous Metal Fabrication Services

· Non-Ferrous Metal Fabrication Services

· Steel Metal Fabrication Services

· Aluminum Metal Fabrication Services

· Bronze Metal Fabrication Services

· Stainless Steel Metal Fabrication Services

· Cobalt Metal Fabrication Services

· Inconel Metal Fabrication Services

· Monel Metal Fabrication Services

· 304/304L Metal Fabrication Services

· 316/316L Metal Fabrication Services

· 4140 Metal Fabrication Services

· 1020 Metal Fabrication Services

· 8620 Metal Fabrication Services

· 1045 Metal Fabrication Services

· 309 Metal Fabrication Services

2. Metal Fabrication Services Materials

· 310 Metal Fabrication Services

· 601 Inc. Metal Fabrication Services

· 625 Inc. Metal Fabrication Services

· 50/50 (657) Inc. Metal Fabrication Services

· 825 Inc. Metal Fabrication Services

· WC6 Metal Fabrication Services

· WC9 Metal Fabrication Services

· Tool Steels Metal Fabrication Services

· A-2 Tool Steel Metal Fabrication Services

· D-2 Tool Steel Metal Fabrication Services

· M-2 Tool Steel Metal Fabrication Services

· O-1 Tool Steel Metal Fabrication Services

· 303 Stainless Metal Fabrication Services

· 5355 Stainless Metal Fabrication Services

· 17-4 Stainless Metal Fabrication Services

· 416 Stainless Metal Fabrication Services

Our Mission:

Create superior value for our customers, partners, employees

To become the most respected and successful metal forming and processing company in China.

Our Values:

· Honesty and Practicality

· Persevering Unremittingly

· Teamwork Spirit

· Long-term Cooperation

· Achieving Greatness

· Expanding our offerings to enable customer success through integrated and differentiated solutions

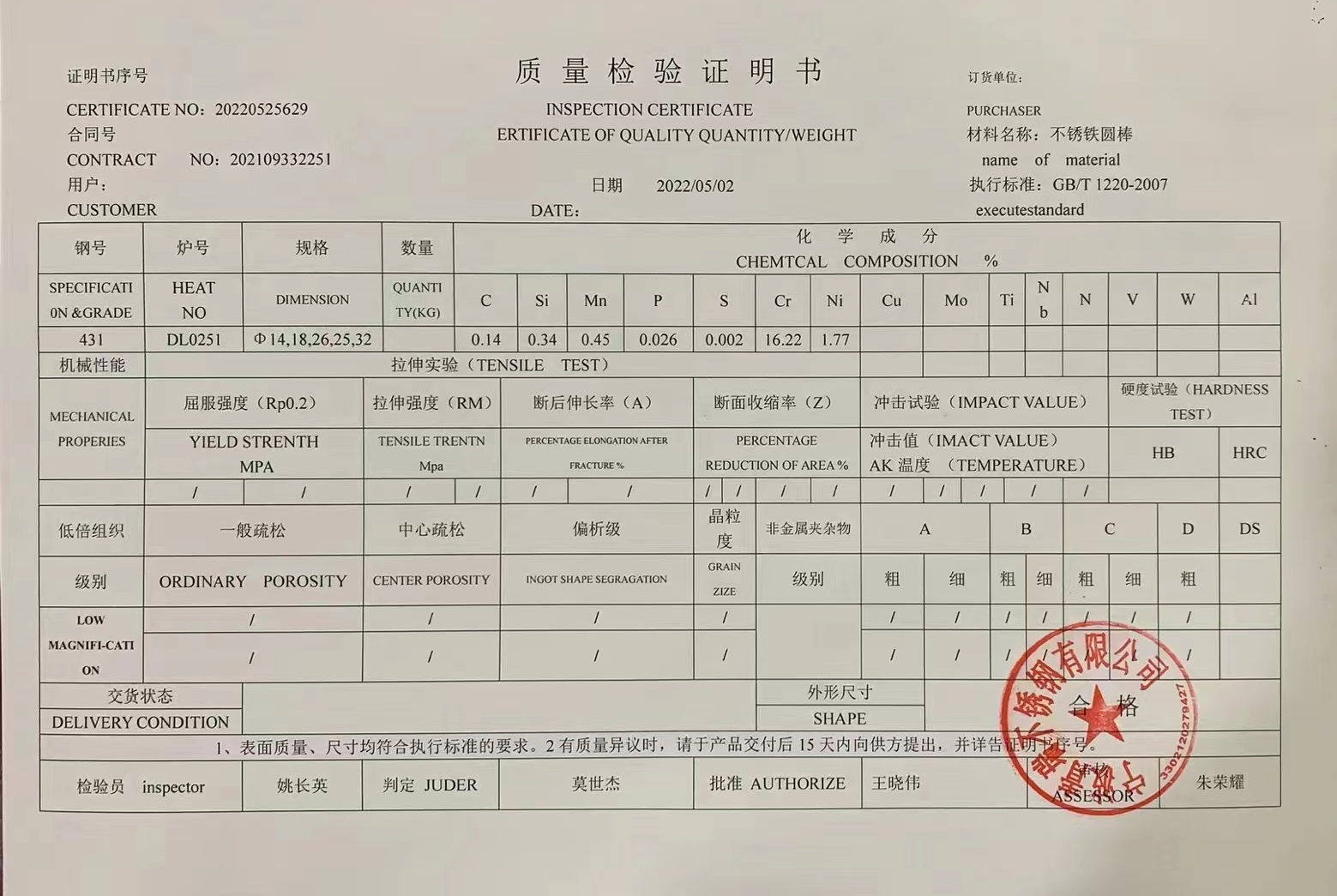

We also provide Material Report for products we supplied.

1. Material report refers to a report that can describe in detail the content of various substances contained in materials, as well as their physical and chemical properties. The most common is the material report. Material report sheet: A report sheet that can detail the content of various substances contained in the material, as well as its physical and chemical properties, is called a material report sheet. Attached:

2. Material report sheet: A report sheet that can describe in detail the content of various substances contained in the material, as well as its physical and chemical properties, is called a material report sheet.

3. The material report is the material report. Material report sheet: A report sheet that can describe in detail the content of various substances contained in the material, as well as its physical and chemical properties, is called a material report sheet. For Example Below